- Home

- Scotland's changing climate

- Urban Housing in Scotland

- Maintenance

- Ventilation

- Airtightness

- Insulation

- Lofts - insulation at ceiling level

- Lofts - insulation at rafter level

- Cavity wall insulation

- Solid Walls: Internal vs External Insulation

- Internal Solid Wall Insulation (IWI)

- External Solid Wall Insulation (EWI)

- Timber frame retrofit

- Windows and doors

- Openings in 'historical' buildings

- Openings in 'non-historical' buildings

- Ground floors

- Suspended floors

- Suspended floors - from below

- Suspended floors - from above

- Solid floors

- Insulation materials

- Building science

- Space heating

- Solar energy

- Product Selector

Why 'Airtightness'?

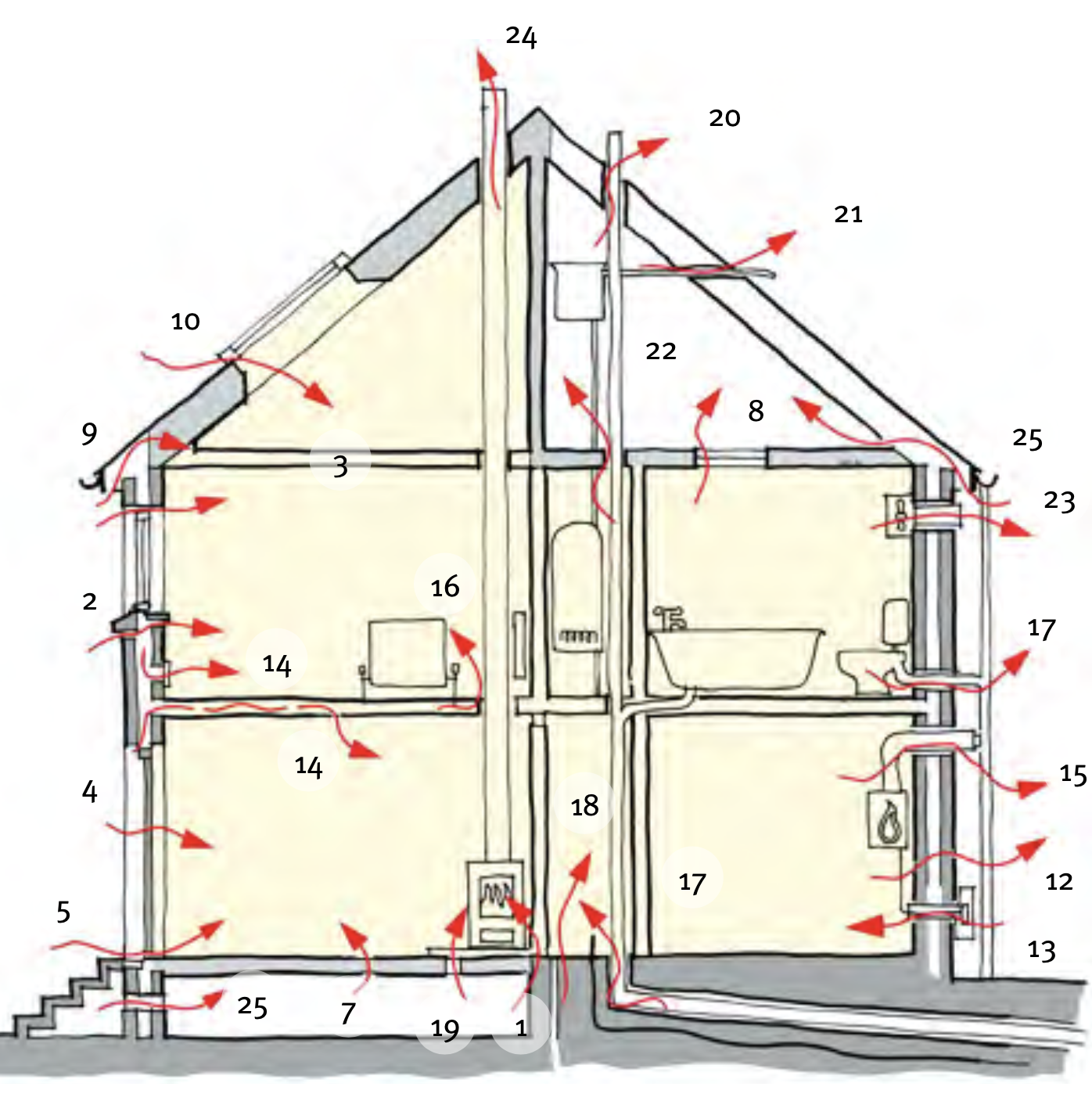

Airtightness is an issue in every part of the building. Where it occurs in roofs, floors, walls and windows, this guide makes recommendations in the relevant section, but as a subject, it needs to be introduced separately.

Airtightness is inextricably bound up with the issue of ventilation and although they are dealt with separately in this guide, it is important to emphasise from the outset that they need to be considered together. As the saying goes: “Build tight, ventilate right.”

“Build tight, ventilate right.”

Diagram indicating the many ways in which air can infiltrate a building with a cavity wall (key to right)

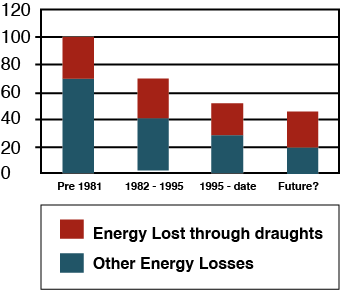

As an issue, airtightness has come to the fore in the last five or ten years in Scotland, creeping first into large-scale non-domestic regulation and now into domestic new-build regulation. It is a welcome development because of the scale of heat loss associated with draughts. As insulation levels have increased since the 1980s, the proportion of heat lost due to draughts has increased to the point where it made no sense to increase the insulation levels required without addressing airtightness. It doesn’t matter how much insulation you put in a building if the heat can bypass it through gaps and holes around the edges.

- gaps between floor joists and the inner leaf of the external wall can connect with gaps throughout the building

- gaps and poorly sealed membranes around, but especially beneath windows and window cills, leak to the outside or into the cavity

- leakage through window openings due to ineffective or missing draughtproofing, through hollow (plastic or metal) frames themselves

- leakage through doors, especially the meeting stiles of double doors

- gaps beneath and around doors

- cracks around skirting boards linked to gaps around the edges of suspended floors

- leakage through suspended floors, typically bare timber floorboards

- gaps around loft hatches

- leakage from eaves into attics often via cavities and behind plasterboard, indirectly into rooms

- gaps around rooflights, e.g. where the rooflight frame is not sealed to the adjacent rafters

- cracks where dissimilar structural elements such as columns meet floor slabs

- leakage through porous masonry leaves, e.g. perpends not filled, often linked to gaps behind drylining, in timber frame buildings eg where a vapour check is torn or not sealed.

- gaps in the external wall at services entry

- leaks around sockets, ceiling roses, recessed spotlights and switches between a warm room and roof space / intermediate floor/cavity

- gaps around boiler flues (in walls and roofs)

- small gaps where water/heating pipes enter rooms from floors, walls and boxed-in spaces

- gaps around waste pipe penetrations e.g. behind toilets, baths and kitchen sinks

- service entry points, even in concrete slabs within a larger diameter pipe

- airbrick/air entry to open-flued fires required by the regulations admit air at all times, not just when the fire is in use

- large gaps where soil pipes/ventilation flues penetrate the roof

- other roof penetrations eg overflow pipes

- gaps between heated spaces and a cold loft where water pipes and cables pass between, often in airing cupboards

- poorly sealed wall-mounted extract fans, also ducted extract from cooker hoods, tumble driers, etc allow air directly into and out of the room, but also into the cavity

- chimneys and flues, if not sealed, will allow leakage at all times

- air movement into an attic and beneath a suspended floor is desirable, but excessive draughts can exacerbate other problems

The heat loss (and other problems) associated with draughts is enormous. Although common estimates put air leakage at around 10% of total building heat loss, this is usually because air leakage associated with other components (roofs, windows, walls, etc.) is counted as part of that element. Taken as an isolated item, the proportion of heat loss in a typical building due to draughts is roughly 40%. This means that for every £100 spent on heating bills, £40 is due to air leakage. Also, as buildings are responsible for around half of all UK carbon emissions, and draughts are responsible for nearly half of that amount, then draughts are responsible for almost a quarter of all UK carbon emissions, comparable to all carbon emissions associated with transport, that is, all car, bus, and train journeys, every year. So, while airtightness can feel like a rather mundane subject, it is also extremely important.

Beyond regulatory compliance, the advantages of making a building more airtight include:

- reduced heating bills and carbon emissions

- greater comfort levels

- reduced requirement for heating system, potential capital cost savings • better control of conditions internally, more reliable, less affected by weather

- decreasing risks of fabric deterioration.

This last point needs to be addressed and bears further mention. Leaky buildings allow cold air in and warm air out, losing heat and causing discomfort. However, that warm air going out was also often relatively moist. This moisture can reach colder outer parts of the construction, where it cools and condenses, leading to a build-up of moisture within the fabric. This moisture, in turn, can lead to several unwelcome outcomes, including:

- decay of organic materials, usually timber frames, joists and rafters embedded in masonry

- saturation of insulating materials, reducing their ability to resist heat

- corrosion of metal components

- frost damage, such as spalling masonry on the cold side of the insulation.

Another reason airtightness is important is that it is usually the most cost-effective way to reduce energy consumption. The difference between the construction costs of creating a leaky and an airtight one

is perhaps no more than 1%, yet it could mean a 40% improvement in performance. For those looking for “quick wins”, there isn’t a more cost-effective solution.

Airtightness and ‘Stuffiness’

The issue of airtightness is a little controversial, and it is worth briefly reviewing this to enable readers to form their own views on an important subject. Many people intuitively sense that an airtight building would necessarily be 'stuffy' inside.

Remember that any building has two forms of air movement: ventilation and infiltration (draughts). An airtight house with poor ventilation (windows fixed shut / fans not working) will soon become stuffy. A draughty house with the same ventilation problems will also become stuffy, although it might take a little longer. Most of us have experienced stuffy spaces, and these experiences were likely in 'normal' (i.e. quite draughty) places. The problem was probably an excess of people or inadequate ventilation, but it wasn't due to airtightness. An airtight home with good ventilation will be fine, just as a draughty house with good ventilation will be fine (if a little colder!). Stuffiness is related to poor ventilation – which can be resolved – not so much to airtightness.

However, the threat of ‘stuffiness’ in retrofitted homes is real, and this is not just an inconvenient thing, it can be very serious when it leads to increased risks of mould and respiratory problems like asthma and Chronic Obstructive Pulmonary Disease (COPD).

The risk is real in retrofit projects because ventilation is not normally considered as part of the retrofit process – geared as it is towards energy efficiency only. Because ventilation is not generally considered part of making buildings more energy efficient, retrofitted buildings can be made much more airtight without a concomitant ventilation strategy. In other words, they are building tight but not ventilating right, which often results in poor air quality, dampness and mould. The finger of blame is pointed at the airtightness, but it is a lack of adequate ventilation. Until the two are considered together, the risk of airtightness getting a bad name remains.

Example of mould/damage due to cold air behind plasterboard or window reveal