- Home

- Scotland's changing climate

- Urban Housing in Scotland

- Maintenance

- Ventilation

- Airtightness

- Insulation

- Lofts - insulation at ceiling level

- Lofts - insulation at rafter level

- Cavity wall insulation

- Solid Walls: Internal vs External Insulation

- Internal Solid Wall Insulation (IWI)

- External Solid Wall Insulation (EWI)

- Timber frame retrofit

- Windows and doors

- Openings in 'historical' buildings

- Openings in 'non-historical' buildings

- Ground floors

- Suspended floors

- Suspended floors - from below

- Suspended floors - from above

- Solid floors

- Insulation materials

- Building science

- Space heating

- Solar energy

- Product Selector

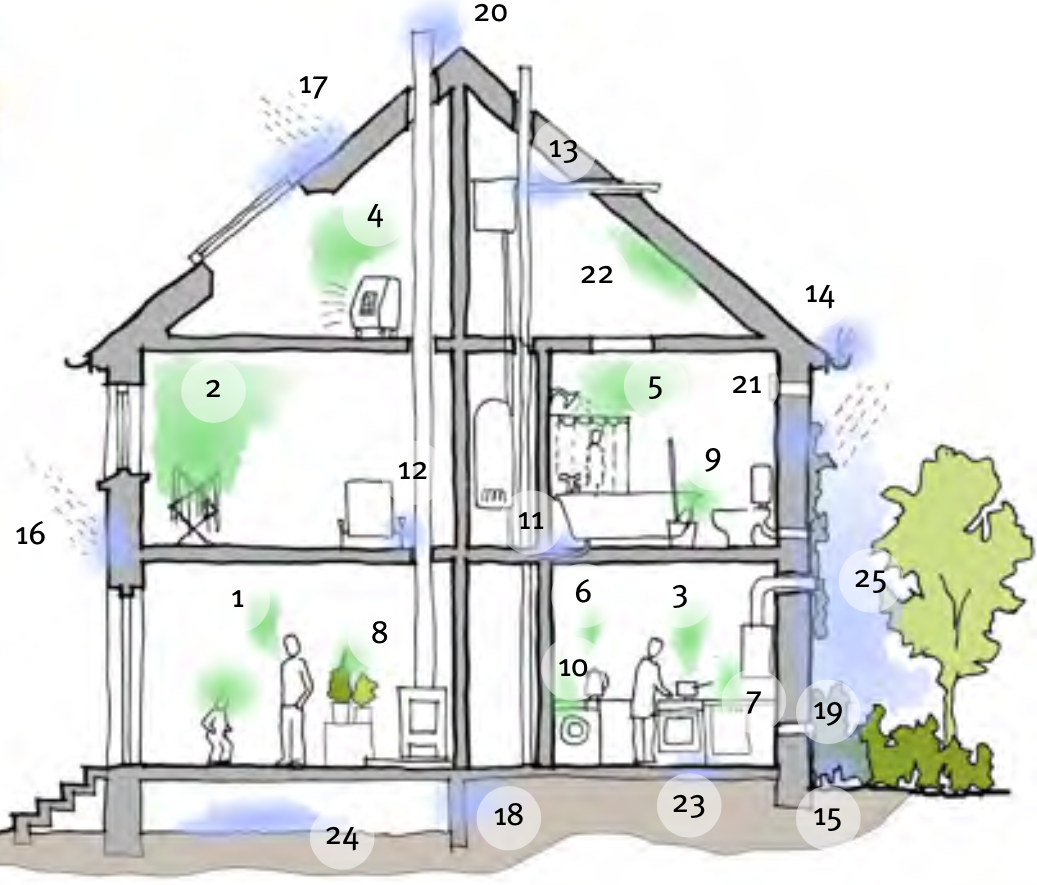

Moisture

Water vapour is water in its gaseous form and is almost always in the air, both inside and outside. The amount of vapour in air at any point is known as the absolute humidity level and is measured in grams per cubic metre (g/m3). When air is carrying as much water as it can, it is said to be saturated and beyond this level, the vapour will condense out of the air, i.e. change to its liquid state.

However, the amount of vapour that air can contain increases with temperature, and so in practice, it tends to be relative humidity (RH), described as a percentage of the total capacity at that temperature, rather than absolute humidity, which is generally used when describing water vapour in the air. The difference in the carrying capacity of vapour is quite dramatic; air at -10o can carry 2.3g of water, while air at 25o can hold ten times more vapour than air at -10o.

Condensation on the inside of windows is common to just about everyone.

Liquid & Solid Water

Water in liquid form mainly affects us as rain, but also when water pipes leak, groundwater seeps upwards into walls and floors and, importantly, as condensate. Solid water takes the form of snow and ice. Snow tends to be handled in the same way as rain, although it can settle and add to the weight loads on roofs, and ice can cause spalling when it forms near the outside face of the masonry.

An important part of building design is keeping rain safely away from the vulnerable parts of the construction. Thus, roof finishes, flashings, rainwater goods, renders and damp-proof courses and membranes are routinely installed to keep buildings dry. However, every one of these is subject to deterioration, movement and weathering, so maintenance becomes critical to managing moisture in buildings. The diagram above shows the range of potential sources of moisture inside a building. Those in vapour form from inside the building are shown in blue-green, while those in (liquid) water form, mainly from outside, are shown in blue.

1. breathing & perspiration

2. clothes drying

3. cooking

4. portable gas heating

5. bathing

6. kettles

7. dishwashing

8. plants (& soil)

9. floor / surface washing

10. washing machine / tumble dryer (depending on venting arrangement)

11. leaks in waste drainage (eg bath connection or toilet cistern) or overflowing bath / basin

12. plumbing leaks - water supplies or central heating

13. burst (frozen) pipes in uninsulated areas

14. gutters leaking / blocked / overflowing or downpipes leaking /blocked eg at fixings

15. gullies blocked / ground nearby saturated

16. rain direct onto walls, in via gaps /cracks in pointing or render

17. rain direct through roof, via missing slates / leaking flashings etc.

18. groundwater via inadequately waterproofed low level walls or floors.

19. ‘rising damp’ driven up walls

20. rain via uncapped chimneys / flues/ flashings etc

21. condensation in wet rooms / cold surfaces / poor ventilation

22. condensation in colder areas / cold surfaces / poor ventilation

23. ‘built-in’ moisture from construction

24. flooding / high water tables

25. high moisture levels to shaded /unventilated areas (overgrown / to north)

Water and Vapour Flow

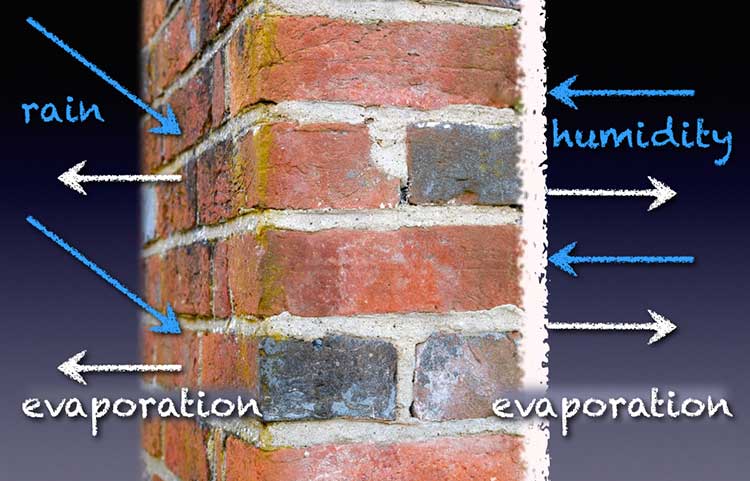

Any home has two sets of moisture movement, as indicated in the drawing above. The first relates to rain and snow; the techniques to keep this water out have mostly stayed the same over the years. Modern methods and materials are as effective as traditional methods but tend to rely less on regular maintenance, which is where the problem can sometimes arise as retrofit projects – by definition – involve older buildings, which tend to need regular maintenance more than some modern designs.

The second relates to water vapour and mainly affects the inside of the home. This is being heated to a higher temperature than outdoors (so the air within can contain more moisture). A fair bit of moisture is generated (from the above sources), creating a situation where warm, moist air exerts a higher vapour pressure, which is then ‘pushed’ outwards against the building fabric.

Two risks are associated with this outward expansion of warm, moist air. The first is to the internal contents and finishes of the home, and the second is to the fabric of the building itself. An example of the first type of risk is where air at 25o and 100% RH inside a house encounters a surface sufficiently cold to cool the adjacent air. Around 12o or below surface temperatures will present this risk in a typically heated home. Common places include a window frame, areas behind large furniture where poor air circulation, or somewhere with a thermal anomaly – missing insulation, a thermal bridge or air gap where cold air is getting in and cooling the internal surfaces. This colder surface cools the adjacent air, which is already at 100% RH, so it has no more capacity to contain the water, and it condenses out, going on over time to form stains and potentially mould.

The second risk is known as interstitial condensation and is essentially the same process of warm, moist air cooling in contact with cold surfaces, but in this case, it happens within the building fabric. Warm, moist air from inside escapes through cracks in the internal surfaces or by diffusion through materials. It works its way outwards until it reaches materials and surfaces near the outer face of the wall, which are colder. At this point, the excess moisture condenses. If this happens on or near timber, there is a risk of decay; near metal, there is a risk of corrosion; and in masonry, it can freeze, causing spalling on the outer faces.

Until perhaps a generation or two ago, this outward pressure of vapour pressure was not as strong (fewer sources of moisture and lower temperatures), and the general draughtiness of buildings, as well as the fact that the fabric of the building was capable of both absorbing and diffusing moisture, meant that this phenomenon was less of an issue. In buildings built or upgraded within the last 40 years or so, and with today’s lifestyles, it is much more of a problem. In general, we keep homes warmer, we generate more moisture and the materials and construction of modern homes are much more vulnerable. This moisture can push its way out through the building fabric, cooling and condensing against impervious materials throughout the construction, causing all manner of problems, most notably the decay of any organic materials therein, such as structural timber frame!

To prevent this, most modern homes employ two techniques to keep buildings safe from internally generated moisture damage. The first is to ensure that wet rooms (kitchen, bathroom, utility rooms, etc.) are fitted with fans that extract any moist air from the source’. The second technique is to ensure that the whole inside of the house is covered with a vapour barrier (VB) or vapour control layer (VCL), which prevents moisture from getting into the building fabric. These techniques work, but they are not without their weaknesses. Fans will only remove moisture if they are operational, and building performance investigators have often found fans to be broken, not extracting effectively or switched off by irritated occupants who dislike the level of noise produced. Equally, vapour barriers only work if they are continuous, and there are countless examples of this not being the case, particularly where the barrier membrane is broken by electrical switch and socket boxes and other service penetrations.

One way to resolve this problem in modern construction is to learn from traditional construction. ‘Breathing walls’ are a relatively recent technique which takes as their starting point the idea that - like traditional construction – if the construction is intrinsically safe from decay, then there is less risk overall, and the techniques designed to protect the construction from moisture (extract ventilation and vapour barriers) become less critical. Breathing walls make construction safer by ensuring that the materials used throughout can safely contain and store moisture, allowing moisture to pass through them to outside safely.

Different materials can also absorb and safely desorb (let out) moisture. This is known as hygroscopicity. Natural material insulations like those made from wood fibre, sheep wool, hemp, flax, etc., are highly hygroscopic and can absorb and store moisture safely, letting it out again and allowing it to pass through, whereas this is not the case with more highly processed insulation materials. Equally, earth and lime mortars and plasters can ‘manage’ moisture, whereas more conventional gypsum and cement mixes cannot, or at least not to the same extent. These characteristics are exploited in breathing construction.

Water vapour moves with air but can also move through solid materials, and breathing walls use this capacity. Movement through materials is known as diffusion and takes place under vapour pressure. The ability of materials to resist the flow of water vapour is measured by their vapour resistivity, which has units of Ns/gm (Newton seconds/ gram. metre). The larger the number, the greater the resistance to vapour flow. The resistivity is the intrinsic level for each material, but this is multiplied by the thickness of a material or component to give the vapour resistance, which has units of Ns/g, sometimes also noted as MNs/g, and this is the unit most commonly used to describe vapour flow through materials. Breathing walls, roofs and floors use materials with quite specific vapour resistance, which decreases from inside to out. This means, in effect, that any moisture finding its way into the building fabric will find it increasingly easy to escape outwards.

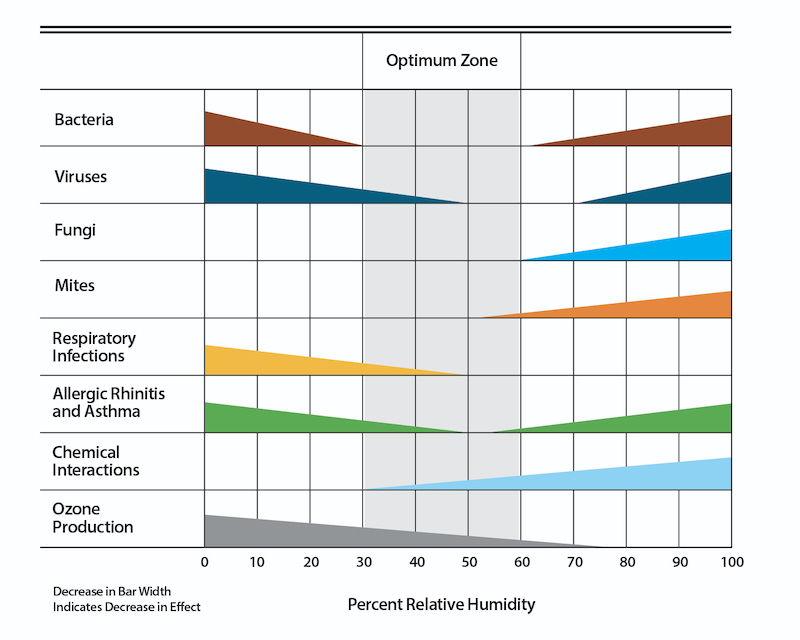

There is another aspect of moisture in the air which is worth mentioning. The diagram right shows that a range of common risks to human health is increased at both extremes of relative humidity (RH). In larger commercial buildings, RH is managed through complex air handling and conditioning equipment, which is rarely an option for houses. Apart from ensuring adequate ventilation at all times (which will tend to ensure that higher levels of RH are avoided), it is also possible to passively buffer the humidity using the natural, hygroscopic materials discussed above. These will absorb water vapour when RH levels are high and desorb it again when the air is drier, helping to balance the RH and reduce risks to the health of those in the house. This technique is usually called ‘humidity buffering’. Several practitioners have used it successfully, particularly in museums containing delicate artefacts such as parchment or other humidity-sensitive materials.

Cables protruding through plasterboard where no service void has been provided meaning the vapour barrier here has been breached.

Traditionally built solid walls are breathable.

Diagram showing the health risks associated with high and low relative humidity extremes

Based on the ‘Sterling Bar Chart’ introduced in “Indirect Health Effects of Relative Humidity in Indoor Environments” by Anthony V. Arundel, Elia M. Sterling, Judith H. Biggin and Theodor D. Sterling. Environmental Health Perspectives, Vol. 65, (Mar., 1986), pp. 351-361.