- Home

- Scotland's changing climate

- Urban Housing in Scotland

- Maintenance

- Ventilation

- Airtightness

- Insulation

- Lofts - insulation at ceiling level

- Lofts - insulation at rafter level

- Cavity wall insulation

- Solid Walls: Internal vs External Insulation

- Internal Solid Wall Insulation (IWI)

- External Solid Wall Insulation (EWI)

- Timber frame retrofit

- Windows and doors

- Openings in 'historical' buildings

- Openings in 'non-historical' buildings

- Ground floors

- Suspended floors

- Suspended floors - from below

- Suspended floors - from above

- Solid floors

- Insulation materials

- Building science

- Space heating

- Solar energy

- Product Selector

The need for Ventilation

Conventional retrofit projects tend to be focused on insulation and energy efficiency. Ventilation is not considered because it is not an energy efficiency measure, but omitting this aspect leads to significant ‘unintended consequences’. Whilst a small number of designers, installers and manufacturers take ventilation very seriously, there is no doubt that most mechanical ventilation installations are poorly considered, poorly installed using barely adequate equipment and then poorly maintained. Because they are often noisy, many are switched off altogether. As a result, a significant majority of homes suffer from poor air quality with, in some cases, severe implications for occupants and the long-term durability of the building itself.

Everyone knows that humans need fresh air. Beyond this fundamental understanding, only some people give the subject very much thought. As a result, it tends to be passed over when considering buildings, environmental performance and the myriad issues which drive retrofit practice. Once again, however, building performance evaluation has highlighted how important ventilation is and how intricately related it is to all manner of problems within the industry and the practice of retrofit. Solve ventilation, and you solve, or at least alleviate many other problems.

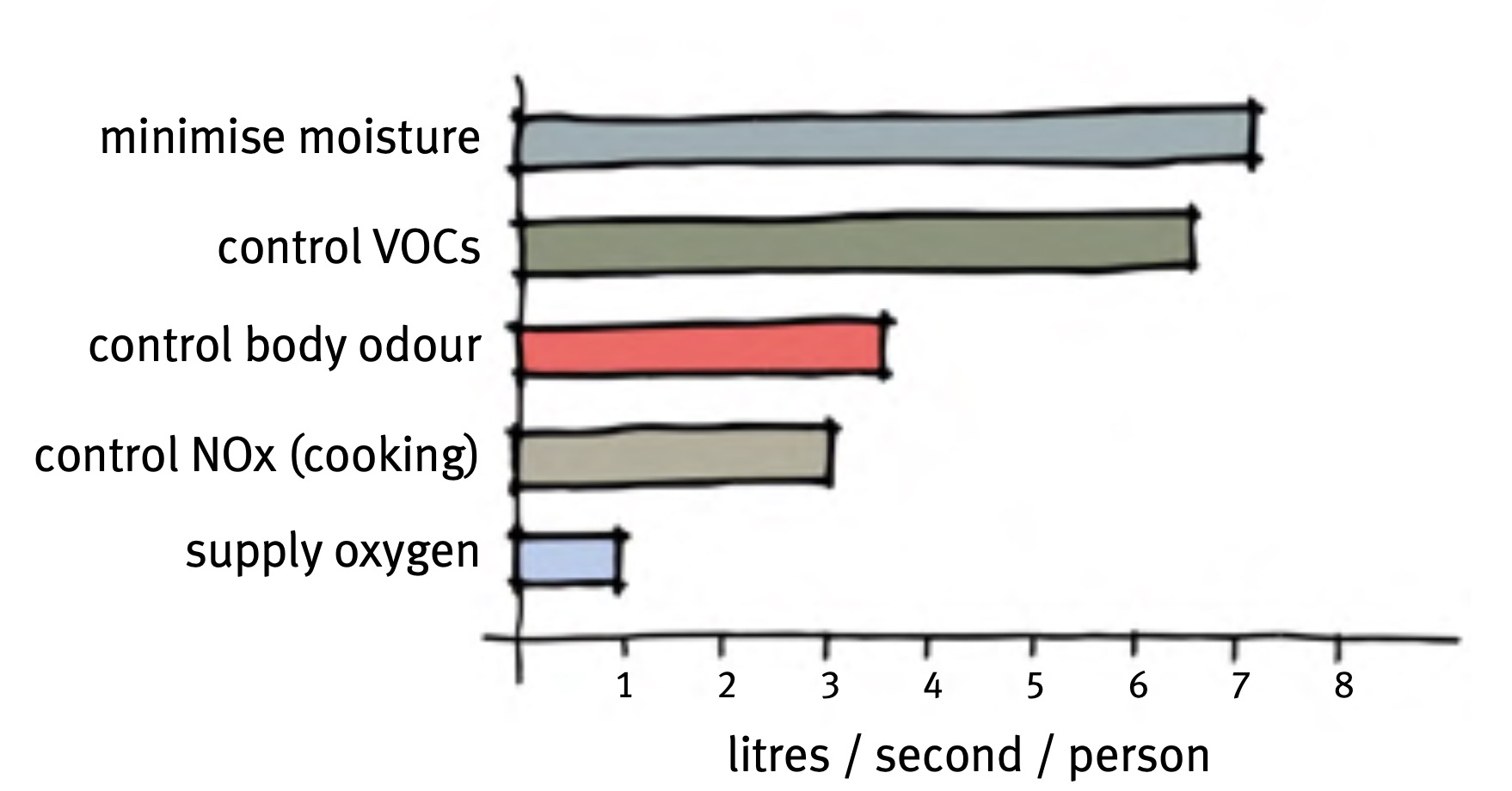

Graph showing 'pollution sources' in a typical home and their relative impact on the ventilation rates required by the building standards (in England and Wales)

The 2006 Approved Document F (Building Regulation in England and Wales) contained a handy graph that no longer features but showed clearly why ventilation is needed and the relative importance of the various pollutants noted. For most people, it is no surprise that the most significant reason we need to ventilate is to remove moisture, but it is a surprise that following close behind is the need to remove volatile organic compounds (VOCs) and other gaseous pollutants emitted from the many synthetic and treated elements of a modern house. At roughly half the significance is the need to control body odour and nitrous oxides from cooking and combustion. By far the slightest reason – but important! – is the need to replenish the oxygen we’ve transformed into carbon dioxide by breathing. There are other recognised benefits of ventilation, not least cooling in warm weather and distributing warmth throughout a home. Still, these aspects tend to be considered as secondary to the primary role of extracting pollutants.

The graph is also helpful in reassuring those who believe that building airtight homes will somehow lead to a reduction in oxygen levels for breathing! A house that is so airtight and poorly ventilated is yet to be built that it will lead to life-threatening oxygen levels. Far more important is that many properties have been built or retrofitted which are sufficiently airtight and poorly ventilated that humidity, air quality linked to VOCs, body odour and NOx (cooking) have become serious problems.

Olfs

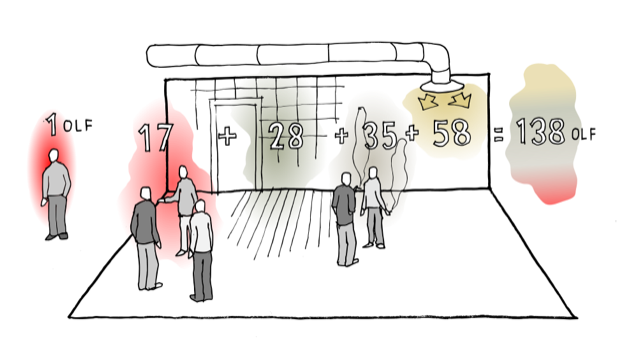

Sketch showing the relative impacts of different ‘pollution sources’ in buildings,

In an office of 17 people, these people emit 17 ‘Olfs’, which must be removed and replaced with fresh air. An additional 28 Olfs are emitted as off-gassing by the synthetic materials and finishes in the room; a further 35 Olfs are emitted if the 17 people smoke. Finally, a vast 58 Olfs are emitted by the intake ducting of the ventilation system itself because such ducts are rarely cleaned. The ventilation system has to be designed to cope with a total of 138 Olfs.

This diagram is based on ‘Olf’s and Their Sources in Office Buildings’ by Prof. Ole Fangar.

A second diagram (above) relates to office buildings. Still, it provides some more insights into ventilation, which are worth mentioning, mainly because of the increased mechanical and often ducted ventilation systems in housing.

The diagram is based on work by Danish building services engineer and researcher Ole Fanger and features the unit known as the “Olf.” Coincidentally similar to Ole Fanger’s name, the word derives from “Olfactory” and describes an amount of air which needs to be removed by the ventilation system to maintain adequate air quality. One ‘Olf’ represents the pollution provided by one person and is an amalgam of moisture generated, body odour, and carbon dioxide. The significance for the ventilation industry is that in any given room, 1 ‘Olf’ needs to be removed for each person in the space. The diagram is based on a typical office in Copenhagen and shows 17 people in a room, so the ventilation system will need to remove 17 ‘Olfs’.

Off-gassing

However, that is only part of the system it must cope with. If everyone in the room smokes, the system capacity has to be tripled to maintain adequate air quality (the work was done in the 1970s and ‘80s when this was more common) while it additionally has to increase capacity again, by almost the same amount, to cope with the off-gassing of synthetic materials and furniture in the building, along with cleaning products etc. Once again, this shows that while most people do not realise the importance of off-gassing of materials, it is a recognised and serious issue and why we emphasise natural and non-toxic materials in this guide. Finally, the punch line is that the ventilation system itself is the source of the largest amount of pollution because the intake ducting is rarely, if ever, cleaned and becomes very dirty, harbouring

an array of pollutants. It must be emphasised that these ventilation systems were air conditioning systems where the air was heated, cooled, humidified and de-humidified. Hence, it is not directly comparable to the simple air ducting of most domestic properties, but the lessons to be learnt are obvious.

Whilst the example is of an office, not a house, and the ventilation is air conditioning, it is hopefully apparent that the risks to health in homes

are similar; people are quite at liberty to smoke in their own homes, all modern buildings contain an equivalent spread of synthetic materials and finishes that off-gas in just the same way, while ducted air systems are becoming more common and maintenance of these is unlikely to be any better. Once again, it shows the importance of maintenance and its complex relationship with energy efficiency and health.

Making it better

A further lesson that can be learnt from this diagram is that if we remove smoking from the equation, use only non-toxic and natural materials and finishes, and either avoid ducted air systems or ensure that they are well cleaned and maintained, then the potential to reduce the need for ventilation – and the associated costs and energy losses – is enormous.