- Home

- Scotland's changing climate

- Urban Housing in Scotland

- Maintenance

- Ventilation

- Airtightness

- Insulation

- Lofts - insulation at ceiling level

- Lofts - insulation at rafter level

- Cavity wall insulation

- Solid Walls: Internal vs External Insulation

- Internal Solid Wall Insulation (IWI)

- External Solid Wall Insulation (EWI)

- Timber frame retrofit

- Windows and doors

- Openings in 'historical' buildings

- Openings in 'non-historical' buildings

- Ground floors

- Suspended floors

- Suspended floors - from below

- Suspended floors - from above

- Solid floors

- Insulation materials

- Building science

- Space heating

- Solar energy

- Product Selector

Suspended Floors - Insulating from Below

Preparation

Access hatches

• Ensure that the access hatch is safely and easily used, and if necessary, enlarge and / or create other hatches. Larger / extra hatches provide more light, convenience and importantly safety. Health & Safety legislation won’t apply if you are insulating your own home. Still, guidance relating to ‘working in small or confined spaces’ is relevant for contractors working on larger projects. The principles of ensuring that working conditions are safe and providing escape in the event of a fire, for example, are reasonably applied everywhere.

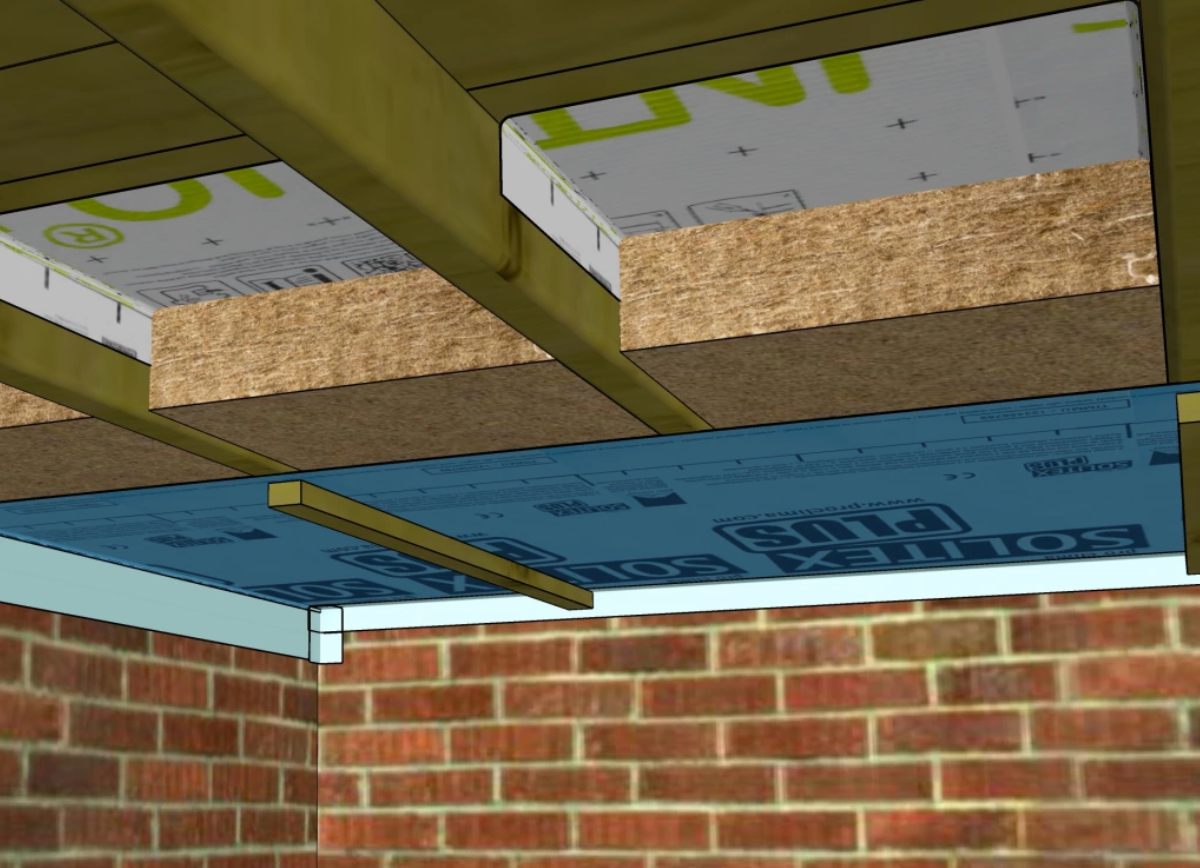

Source: Ecological Building Systems

Tools and light

• Working beneath the floor can be uncomfortable and inconvenient, so it pays to prepare carefully, ensuring all tools required are on hand and sufficient light to work. Battery-powered head torches work well with temporary rigged background lighting.

Ensuring ventilation

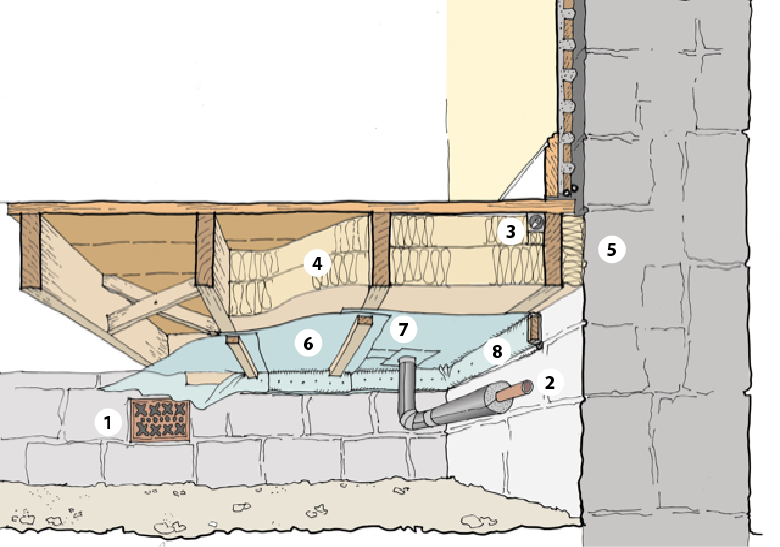

• When insulating between joists in a floor, you are technically increasing the risk of decay because you are keeping them warm and reducing the air flow around them. For this reason it is important to use hygroscopic materials, but also to ensure that the air flow within and across the solum is adequate. As part of the work, ensure that the existing air bricks are not covered or damaged, and that there is an adequate flow of air to all spaces [1]. This means both air flow from outside, but also across the solum, so that air bricks / gaps across internal partition foundations are also important. Construction of additional air bricks and forming gaps for air to pass through within the solum are jobs suitably qualified contractors should undertake.

Review services

• The guidance related to water pipes, electric and telecom cables in lofts applies equally to solum spaces. Ideally, it is worth reviewing all cables and pipework and removing anything redundant while adjusting anything that would compromise the insulation works.

• All water pipes are ideally removed from the solum but this is not always practical. It is important to fully insulate any water pipes [2] (including central heating pipework), as the temperatures in winter within the solum once insulated will be much colder and the risk of freezing increases. Doing so will save energy while improving the ability of the system to heat the building as intended.

• Conversely, the risk for electric cables is that they overheat once insulation is applied. If they are run within the depth of joists then they should be run within conduit to allow some air flow around them, and to allow for upgrading in the future [3]. It is also possible to run cables beneath the joists and insulation. However this can be annoying as work continues because they get in the way and then need to be fixed back once insulation is completed. Telecom cables do not suffer from overheating but should be treated in the same manner.

Joist condition

• It is worth checking the condition of the joists, particularly as they meet the walls. It is quite common for joist ends to require replacement due to decay or infestation and it is wise to allow for this possibility.

Sketch detail showing how insulation and airtightness can be installed to a suspended timber floor where there is access from below

Installation

Leave no gaps with the insulation

• The installation of the insulation itself is relatively straightforward; it is cut to fit neatly and pushed into place [4]. Using a semi-rigid insulation such as woodfibre is much easier than a soft roll type because they will tend to support themselves in the area. The main thing with both types is that they fully fit, leaving no gaps between themselves, the joists and the adjacent walls. Even the smallest gap must be filled, and the insulation should fill the full depth of the posts. Sometimes, joists run close to a wall, and the gaps between them get left out, but these must be carefully filled [5].

Membrane

• The next step is to install the membrane [6]. Many companies provide 'breather membranes' which allow vapour to pass through and these are a step up from netting, but there are also membranes which are also airtight, available from specialist sources, the phrase often used is "wind-tight" and these are preferable.

• The membrane is stretched neatly and tightly across the whole floor and carefully sealed at all laps and, importantly, around all edges where it meets the adjacent wall.

• In order to effectively seal laps, it helps if the laps can be organised to line up with the joists [7]. This allows you to firmly seal using double sided tape as well as the recommended tape over.

• The membrane is typically stapled to the underside of the joists but this is not always a robust long-term solution as the insulation can drop onto the membrane pulling it away from the joists. Ideally therefore, it is best to run a small batten over the membrane at perhaps 1.2m centres or every two or three joists, or over each lap of the membrane, with the batten screwed through the membrane into the joists.

• Sealing the membrane against the adjacent walls is arguably the trickiest bit because walls are generally of masonry, often irregular and usually dusty. If the walls are quite straight and smooth, one solution is to carefully dust down the walls and apply a primer which then allows the membrane to be confidently taped and sealed to the wall. More often, the surface is too irregular, so an alternative is to wrap the membrane around a batten which is mechanically fixed into the wall using a couple of beads of mastic to seal the irregular gap between the two [8].

Fitting a hatch

• As with the loft, the hatch can become a weak link if not carefully treated. A snug fitting ‘box’ needs to be created to mimic the insulation levels elsewhere and ideally, a trim formed for the hatch to drop onto, and seal against air leakage. Here, the simplest solution is often to use rigid insulation cut neatly to shape and fixed to the underside of the floor finish, rather than soft insulation within a framework.

Alternatives

• An alternative is to substitute a vapour permeable board for the membrane. This could be more robust but also potentially more expensive.

• It is also possible to add insulation both above and below the joists. This can be done instead of, or in addition to insulating between the joists. If it is possible to insulate between the posts then this is usually the best solution because it has no knock-on effect on levels and is a robust solution in the long-term if undertaken well. The main advantage of adding or insulating above or below is avoiding the thermal bridging associated with the joists themselves.

• If adding insulation beneath the joists, then it is critical that the insulation is vapour permeable, and the most sensible type to use is a rigid board which can be affixed to the underside of the joists and held in place with battens that are also fixed back to the bottom of the posts.

• Adding insulation above the joists is discussed in the next section.

Health & Safety

Some solums are basements or semi-external spaces where access is straightforward and working practices are essentially normal. As depth beneath joists decreases, however, access and safety issues become more acute. Before carrying out the work, it is important to solum (which can vary across the space to be insulated), and agreeing on a sensible methodology for knowing the depth is important to manage this. Critical issues are escape, general working conditions, air quality and lighting. Most solum spaces are dusty. Almost any work in them will generate dust in the atmosphere, which is a risk to health and makes working more difficult. Clearing debris will raise dust, as will brushing down walls to affix membrane, and any work must address this.

How Much is Enough?

For most projects, filling the depth of the joists will be adequate to save energy and bring benefits to comfort. Most joists in older buildings are between 125mm and 200mm when installed– filling these will provide a reasonable level of insulation. Better than increasing the depth of insulation is to follow the guidance on preventing air leakage to the letter, as this will have benefits beyond the discussion of U-values.