- Home

- Scotland's changing climate

- Urban Housing in Scotland

- Maintenance

- Ventilation

- Airtightness

- Insulation

- Lofts - insulation at ceiling level

- Lofts - insulation at rafter level

- Cavity wall insulation

- Solid Walls: Internal vs External Insulation

- Internal Solid Wall Insulation (IWI)

- External Solid Wall Insulation (EWI)

- Timber frame retrofit

- Windows and doors

- Openings in 'historical' buildings

- Openings in 'non-historical' buildings

- Ground floors

- Suspended floors

- Suspended floors - from below

- Suspended floors - from above

- Solid floors

- Insulation materials

- Building science

- Space heating

- Solar energy

- Product Selector

Timber Frame Retrofit

In Scotland, most new homes are now built in timber frames. Most of these homes feature an internal timber frame filled with insulation, a ventilated cavity outside, and a masonry wall beyond to make it look like a masonry home. The timber frame is the structural element, however, holding up the intermediate floors and the roof.

Advantages of timber frame construction

+ Fast

Above all, it is relatively faster and cheaper to build than masonry. In a country with bad weather, you can get the roof on quickly and be working in the dry sooner. The masonry outer leaf can be put up any time after that and is mainly outside the ‘critical path’ of a build process.

+ Better insulated

Timber-framed homes are generally better insulated than older homes, and timber is a relatively ‘green’ material compared to most masonry options, with less embodied energy.

Disadvantages of timber frame

• Timber burns, of course, and being organic, it can rot or become infested with insects if the conditions are right, and it can move if it’s not installed at the correct moisture content.

• Timber frame walls don’t have the sheer mass of masonry and so have to manage acoustic separation differently.

These downsides are managed through the building control system,d design codes, and manufacturer’s recommendations.

• However, the increase in complexity required by the building regulations and a widespread de-skilling of the construction industry means that while timber-framed homes built in the last 50 years or so are theoretically better performing than older buildings, this is not always the case in reality.

• They can also be more complicated constructionally and less robust, making it harder to devise effective improvements in both cost and performance.

Important to know

Remembering that timber is organic and can decay under the right circumstances is important. This means material choices, air and vapour barriers and ventilation all play a part in keeping the timber and insulation dry and performing well.

Our guidance vs conventional guidance

Topic | Conventional Guidance | Our Guidance |

|---|---|---|

ENERGY | Improve U-values, fill frames if empty. | Improve U-values, fill frames if empty. As Construction below. Importance of airtightness. Potential to upgrade existing insulation in frame (often inadequate) Lambda / U-value less important than continuity of insulation (eg to reveals). Additional insulation resolves thermal bridging of studwork. Natural insulation reduces embodied energy. |

HEALTH | - | Effective insulation reduces cold spots and mould risk internally & improves comfort. The use of natural insulation reduces respiratory health risks. The use of dense insulation reduces fluctuations in temp / RH. |

FABRIC | - | Measures noted in other sections will protect building fabric from long-term problems. |

MODELLING | - | As per Energy and Construction. |

FABRIC | - | As per Energy, Moisture and Construction. |

MOISTURE | - | Continuous VCL and service void installation protects the frame from internal moisture more effectively. |

PEOPLE | - | Invest in upgrading services, etc., before installing insulation (less cost and disruption later). |

CONSTRUCTION | - | Carry out pressure test first, audit to assess, and adjust works accordingly. Allow for potential localised improvement, reflects ‘patchiness’ of some timber frame buildings. |

MAINTENANCE | - | Topping up insulation is a relatively extreme form of maintenance of the insulated fabric. |

SIGNIFICANCE | - | It is unlikely to be problematic unless there are internal finishes of significance. |

There needs to be more guidance on retrofitting timber-framed houses, and what there is quite diverse, often coming from a commercial standpoint and often assuming that there is no insulation within the frame.

As well as improving the U-value, our proposal provides two other benefits:

• By removing the existing plasterboard allows us to ‘top-up’ any slumped, failed or missing insulation within the frame itself - a common problem, especially with older timber frames.

• In addition, it allows us to resolve a principal weakness in most timber frame walls by providing a continuous vapour control layer, not a risk from penetrating services.

Preparation

• Compared to a solid walled house, timber framed buildings are pretty complex constructionally, with many layers that play a different role. This complexity means that it is worth spending a little time investigating before making a decision one way or another.

The most helpful test is an air pressure test because this will determine how much heat loss can be linked to draughts. Results can differ widely and would affect how to proceed.

While doing the pressure test, ensure it includes an audit (usually with a smoke pencil) and thermographic images to assess potential problems and the overall quality of the construction.

• If the reporting above shows that the building suffers from excessive draughts, it makes more sense to tackle these before spending time and money on disruptive insulation improvements. Common areas are discussed in the section on airtightness. Remember when undertaking these works to ensure that ventilation is also considered.

• If the reporting shows that the building is relatively airtight but has localised issues within the walls or other areas, then a targeted approach may be best. It is possible to inject insulation directly into timber frames, but this doesn't allow you to see what is happening, and there are risks of materials used affecting electric cables. Therefore, it is usually better to remove the plasterboard, assess what is there, carefully re-insulate, repair the vapour control layer (if present), put back the plasterboard and re-decorate. It is not too demanding if this is only in one or two areas.

• If the timber frame is uninsulated, then clearly, this is the place to start. Insulating within the frame will make a huge difference, but the following points remain useful.

Installation

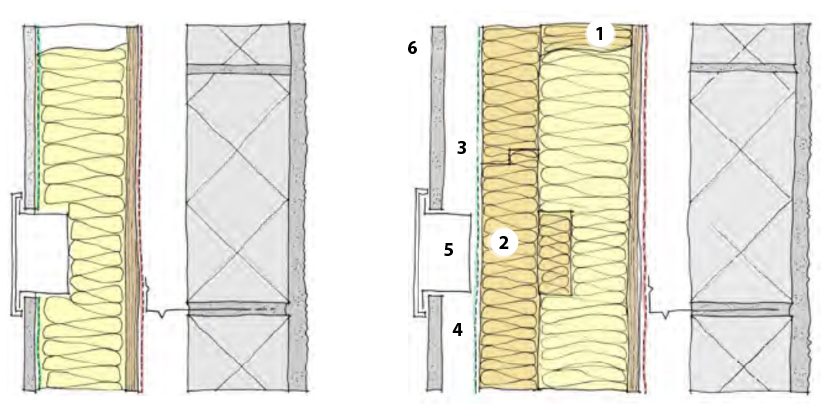

Inspect existing insulation

• Once the plasterboard is removed, it will be possible to inspect the existing insulation and services within the frame and to upgrade or top up any insulation which has slumped or is missing [1]. Comments on the best type of insulation and the need for attention to detail (no gaps), as noted in the roof section, apply here, too.

Add insulation boards

• A layer of ideally interlocking insulation boards can then be affixed over the inner face of the studs. This gives both more insulation and overcomes the studs' thermal bridging effect [2].

• These boards should be fairly rigid to avoid additional woodwork and, ideally, hygroscopic and denser materials (such as wood fibre) to better manage any moisture in the wall.

Insulate window reveals

• As with standard Internal Wall Insulation (IWI), it is important, where possible, to insulate the reveals of windows and seal all gaps, including at service penetrations, etc.

Use ‘intelligent’ vapour control

• The vapour control layer shown inside the insulation [3] should be an ‘intelligent’ type, allowing some vapour ‘back into’ the room under low pressure while maintaining an effective barrier to high levels of vapour pressure into the wall. This is because the external sheathing of the wall is likely to be plywood or OSB, neither of which is vapour permeable, so moisture that gets into the wall cannot escape, as it can in a ‘breathing wall’ (Refer to ‘Building Science’ section ).

Form a service void

• Not only is it critical to have a vapour barrier to stop moisture from getting into the wall, but it is important not to puncture this barrier, and for this reason, we have shown a service void formed of battens inside the membrane [4]. These allow for future changes in servicing and location of electric boxes, etc. [5] without damaging the insulation or the vapour barrier in the long term.

Internal finishing

• The internal finish can then be completed with plasterboard as shown, although another solution would be a clay board, and directly applied plaster finishes are also possible. [6].

Alternatives

Remove masonry & add external insulation

• An alternative is to remove the existing masonry wall (which is rarely structural) and add insulation to the outside of the existing timber frame.

• Obviously, this option involves a lot of work, including the need for local authority approval for both planning and building warrant, as the building will probably look different externally.

• The work will almost certainly affect windows and doors as well as anything connected with the building's external face, including service entry points and the eaves above.

• Insulation boards can be installed directly over the existing sheathing board, reducing the studs' thermal bridges. A new breather membrane is then required over these boards and vertical battens to create a ventilated cavity as before.

Replace sheathing with ‘breathable’ board

• Another alternative that would improve the wall's long-term durability would be to replace the existing sheathing board with a ‘breathable’ board, enhancing the likelihood of moisture escaping safely.

• However, since the sheathing board is needed for racking strength, a structural engineer would be required to advise on a suitable replacement (breathable but also strong enough) and ensure that boards are only removed in stages to prevent frame failure.

Add new cavity and cladding

• It would be possible to rebuild the masonry wall, but this would probably need new foundations and possibly a roof extension,

• So, the most likely scenario is that a new, lightweight cladding is used over the new cavity. This could be timber, metal or any number of board materials, the advantage of all being that – as long as the structural engineer agrees – these can all be fixed back to the existing frame and no new foundation will be required.

Health & Safety

• There are risks associated with demolition dust and potentially from breathing in the fibrous dust of the existing insulation. If working externally at height, there are associated risks and issues related to disconnecting and re-connecting services.

How Much is Enough?

• Unless there is a particular U-value target to be reached, around 100 mm of additional insulation is usually sufficient, assuming the frame already has around 150 mm of insulation within. In Passivhaus-standard retrofits, this might need to be thicker. What is much more important than the precise depth of the insulation is the continuity of the insulation.